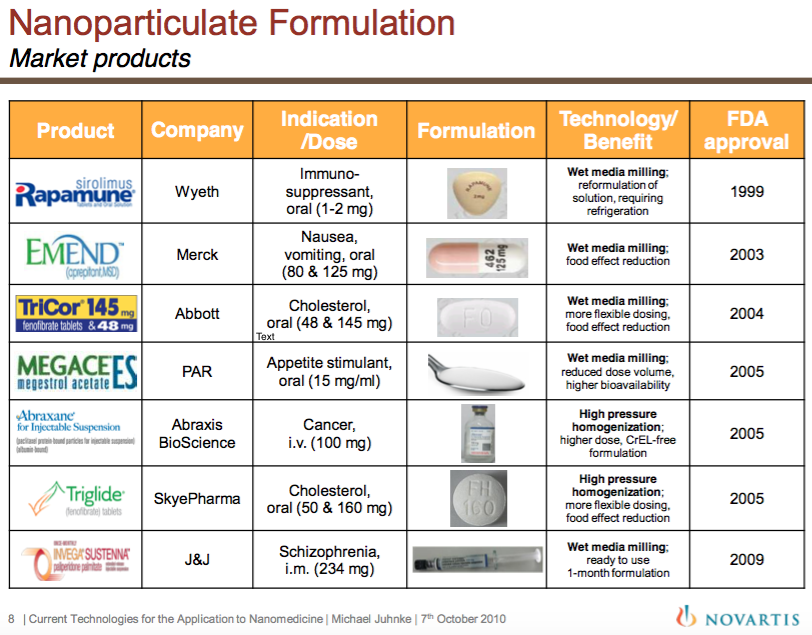

應用實例:

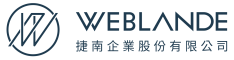

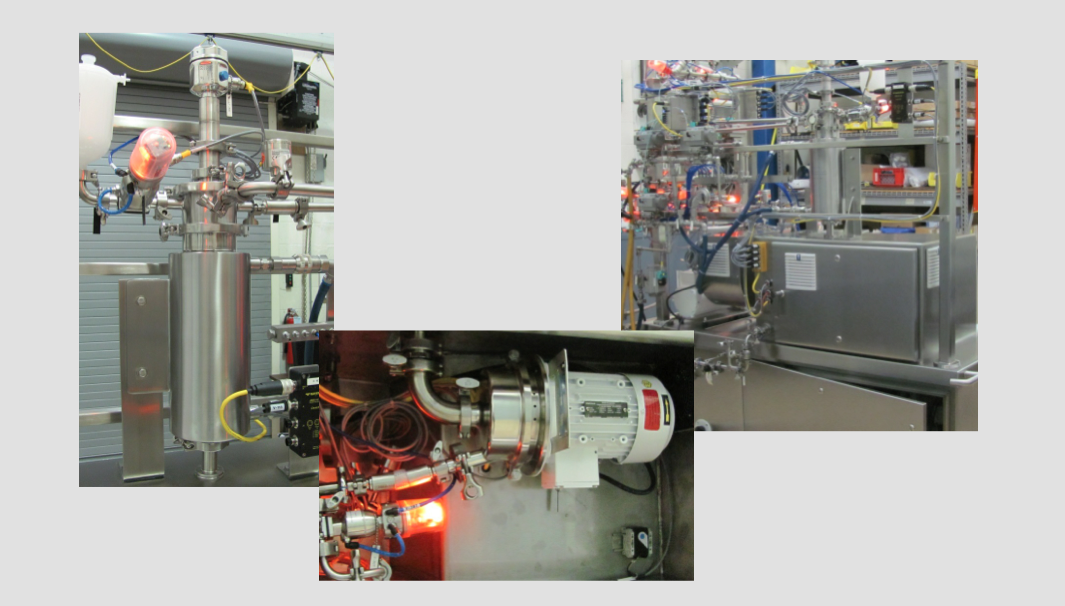

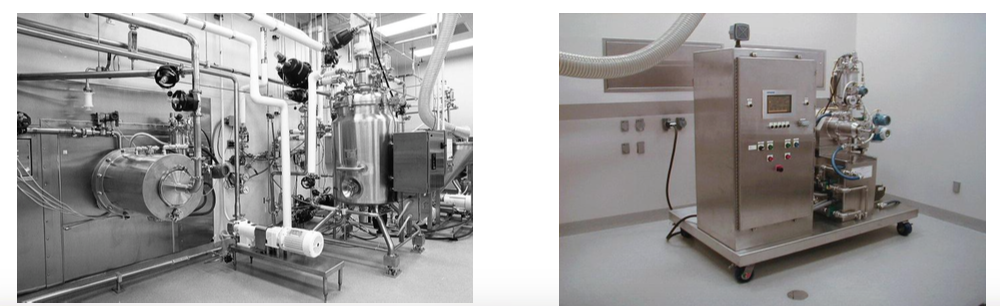

實際安裝

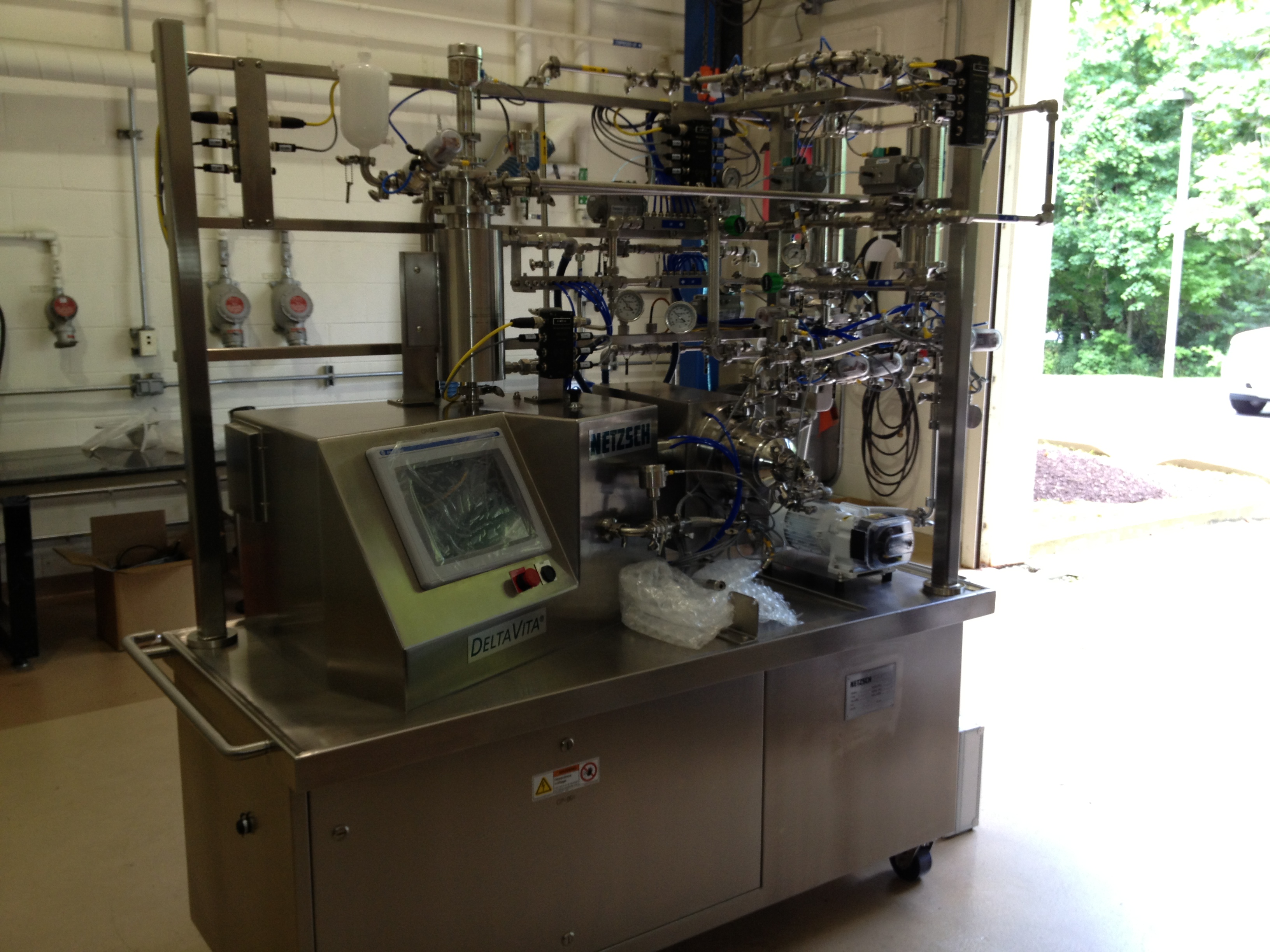

奈米製藥 實驗/量產型設備

Grinding and Dispersing of Pharmaceuticals

NETZSCH DeltaVita

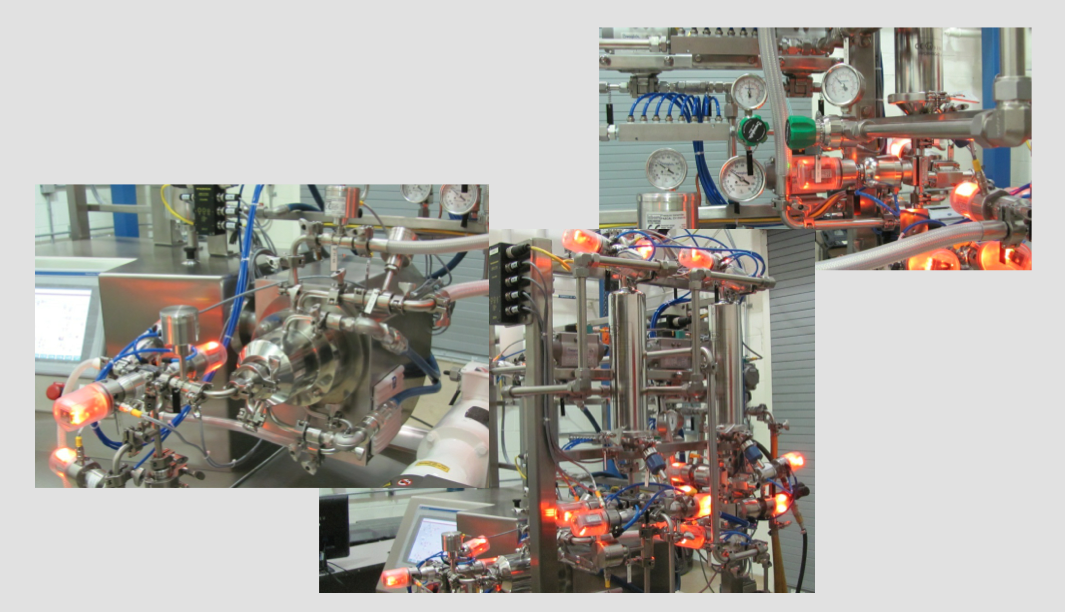

Based on comprehensive experience with the production of GMP-compliant pharmaceutical products, all sizes of NETZSCH DeltaVita machines ranging from small laboratory- to production-size machines excel by the following specific features:

- All product wetted parts are designed and manufactured according to the latest GMP standards

- Material-, production- and calibration certificates are supplied together with the machine

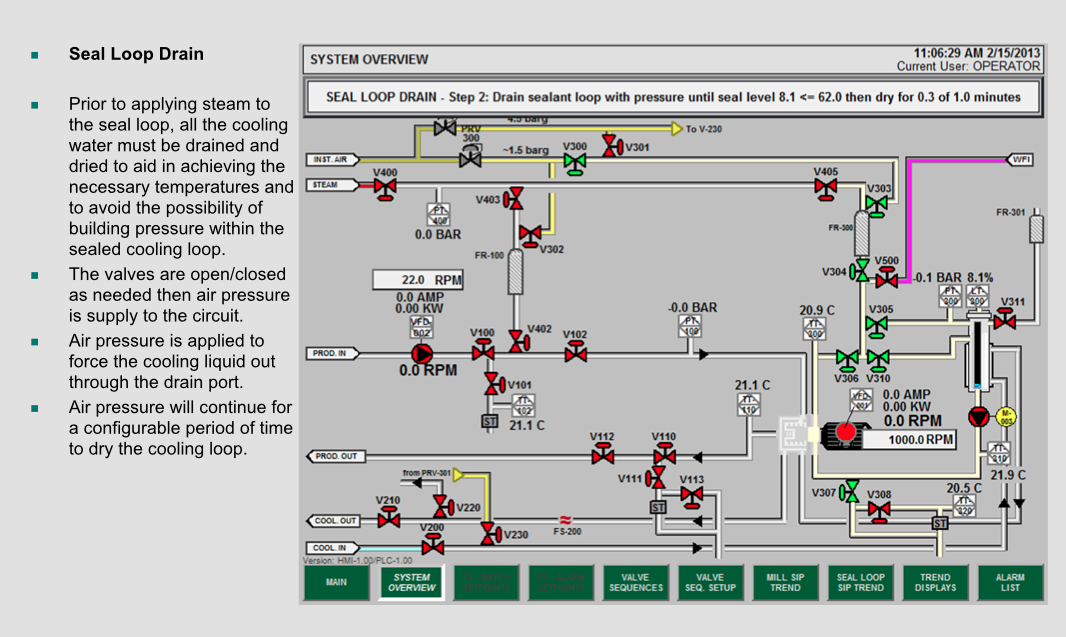

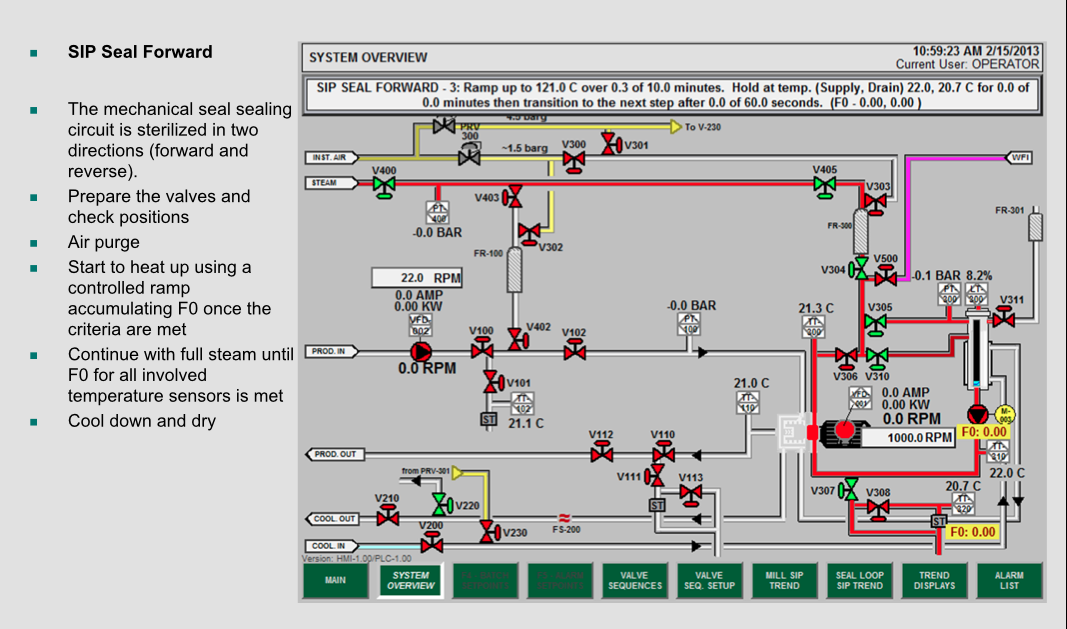

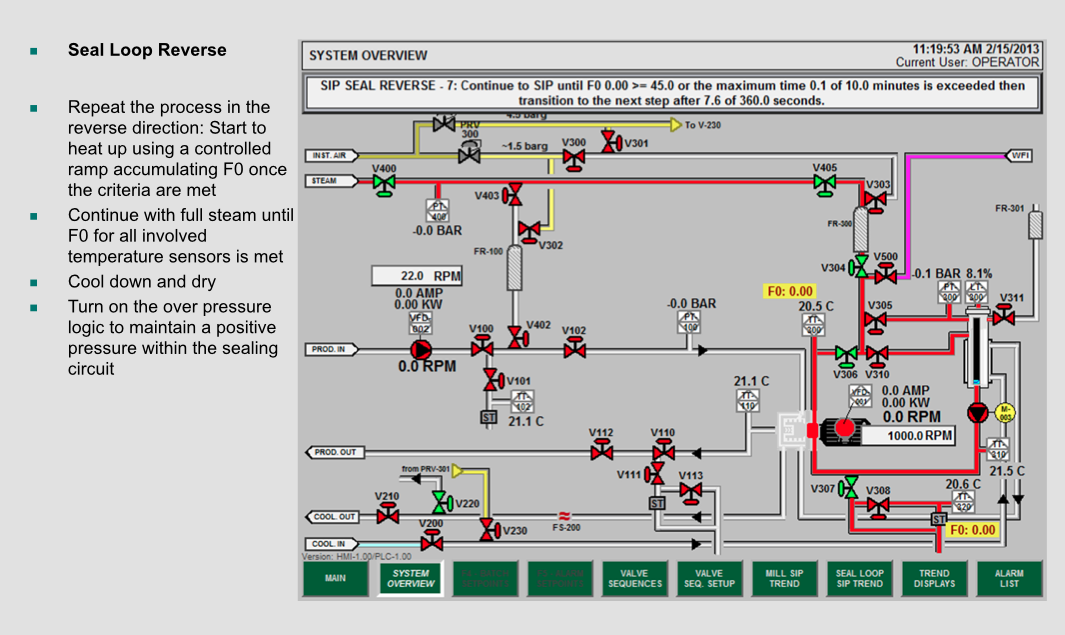

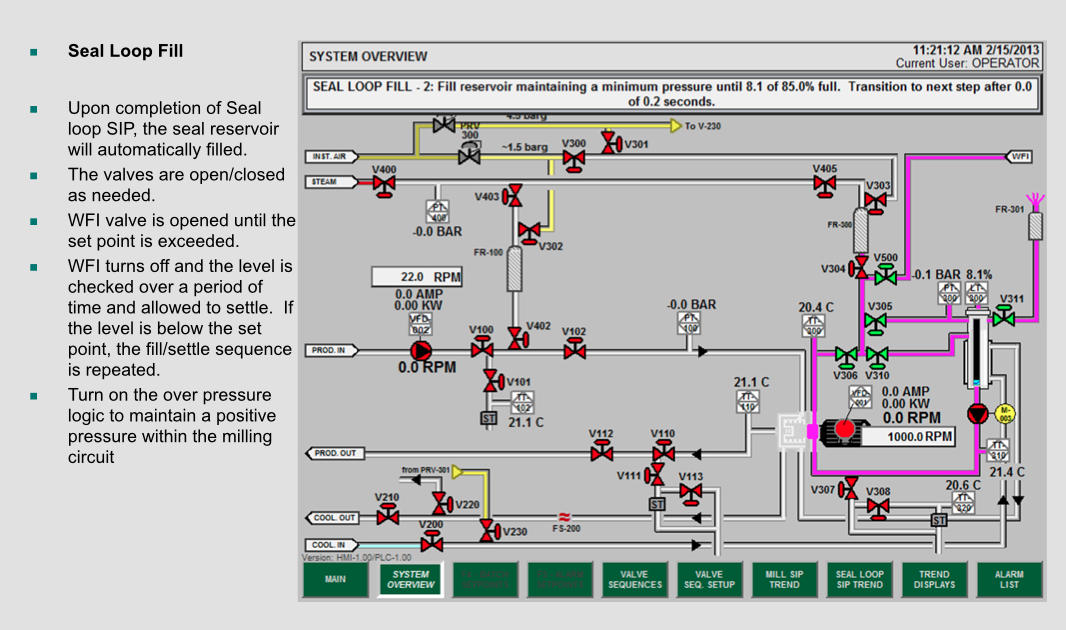

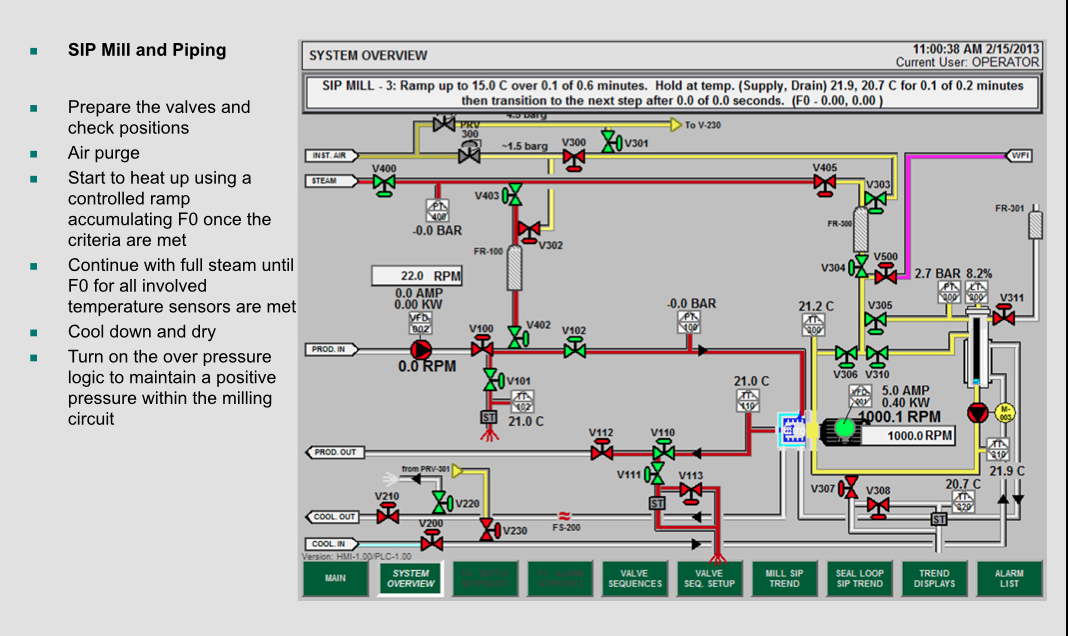

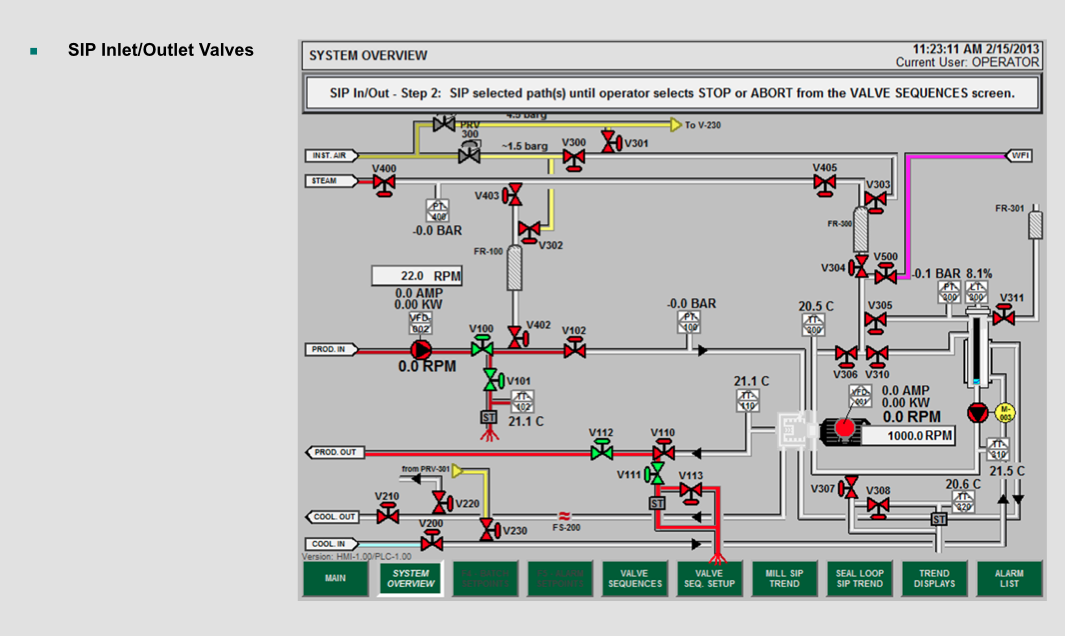

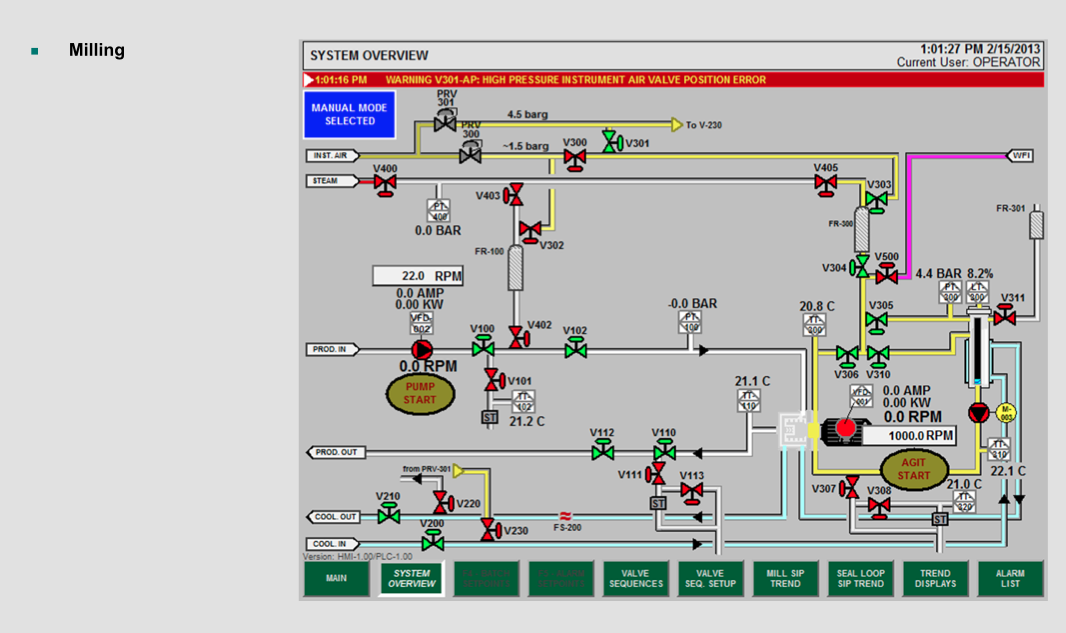

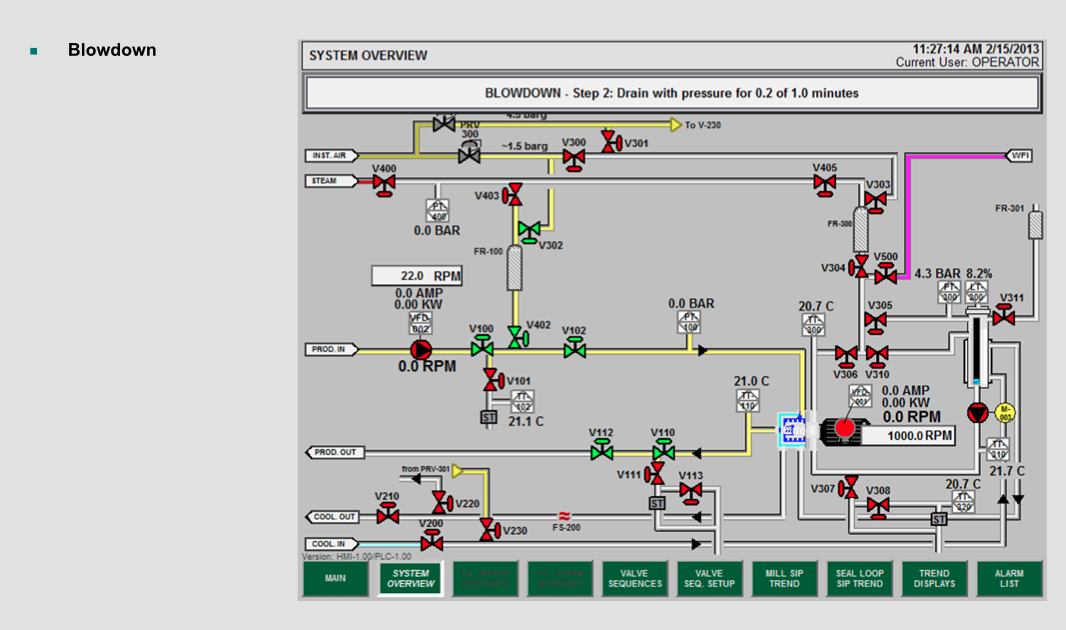

- Optional cleaning in place (CIP) and sterilization in place (SIP)

- All indirectly product-wetted surfaces are made of stainless steel

- Optional data recording and formulation management

- Operator management with password protection for different levels of security

- Laboratory mills can be used with variable grinding chamber sizes

- Various materials like ZrO2, stainless steel 316 or nylon grinding chamber designs are available

- Splash-proof machine stand

- Comprehensive testing and qualification documentation, FAT, IQ, OQ, process validation

- Production of GMP compliant machines in the USA

- Trainings and seminars

DELTAVITA Technology

|

DeltaVita® 15 – 300 (Lab scale)

DeltaVita® 600 (Trial production)

DeltaVita® 2000 – 60000 (Production units)

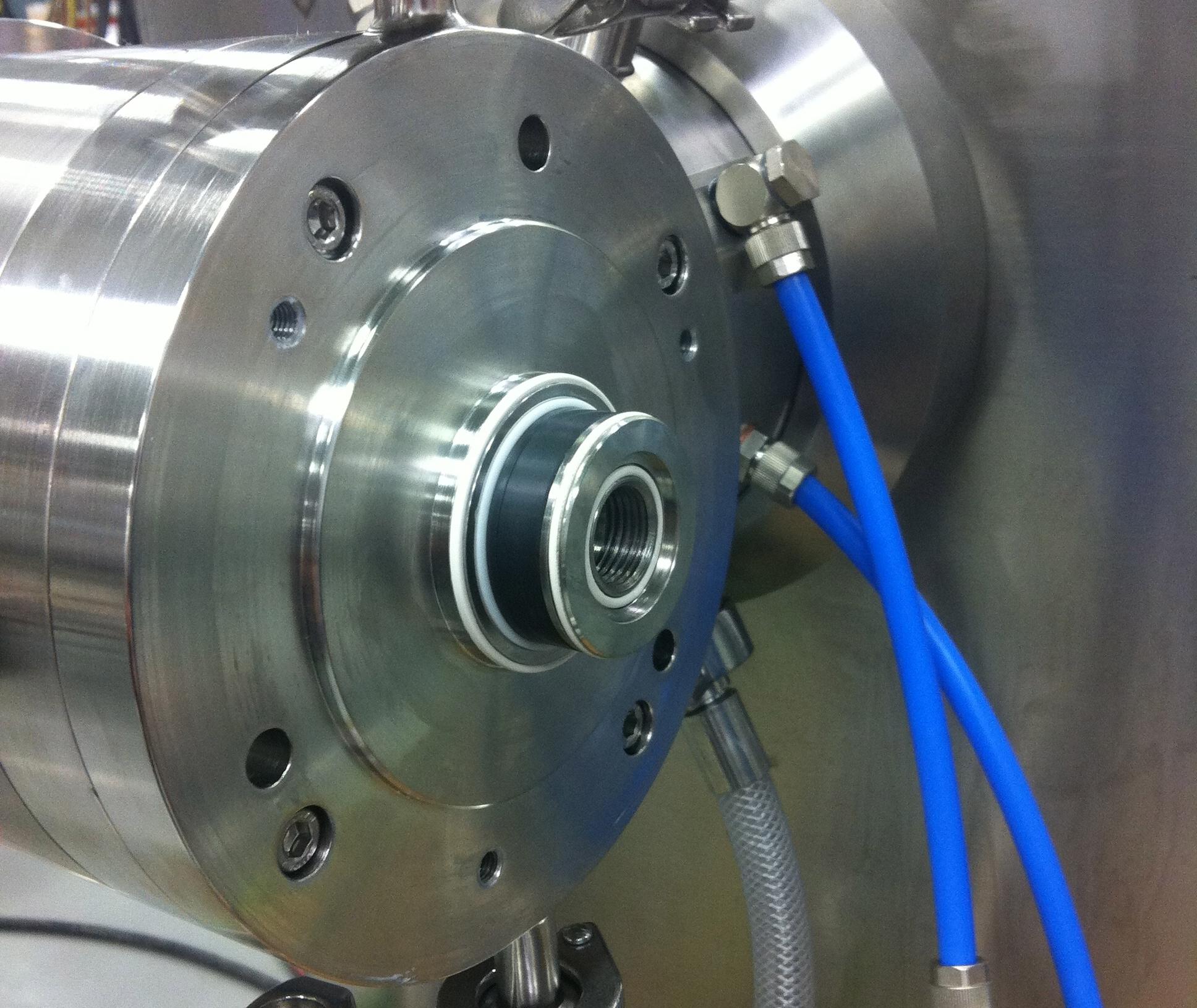

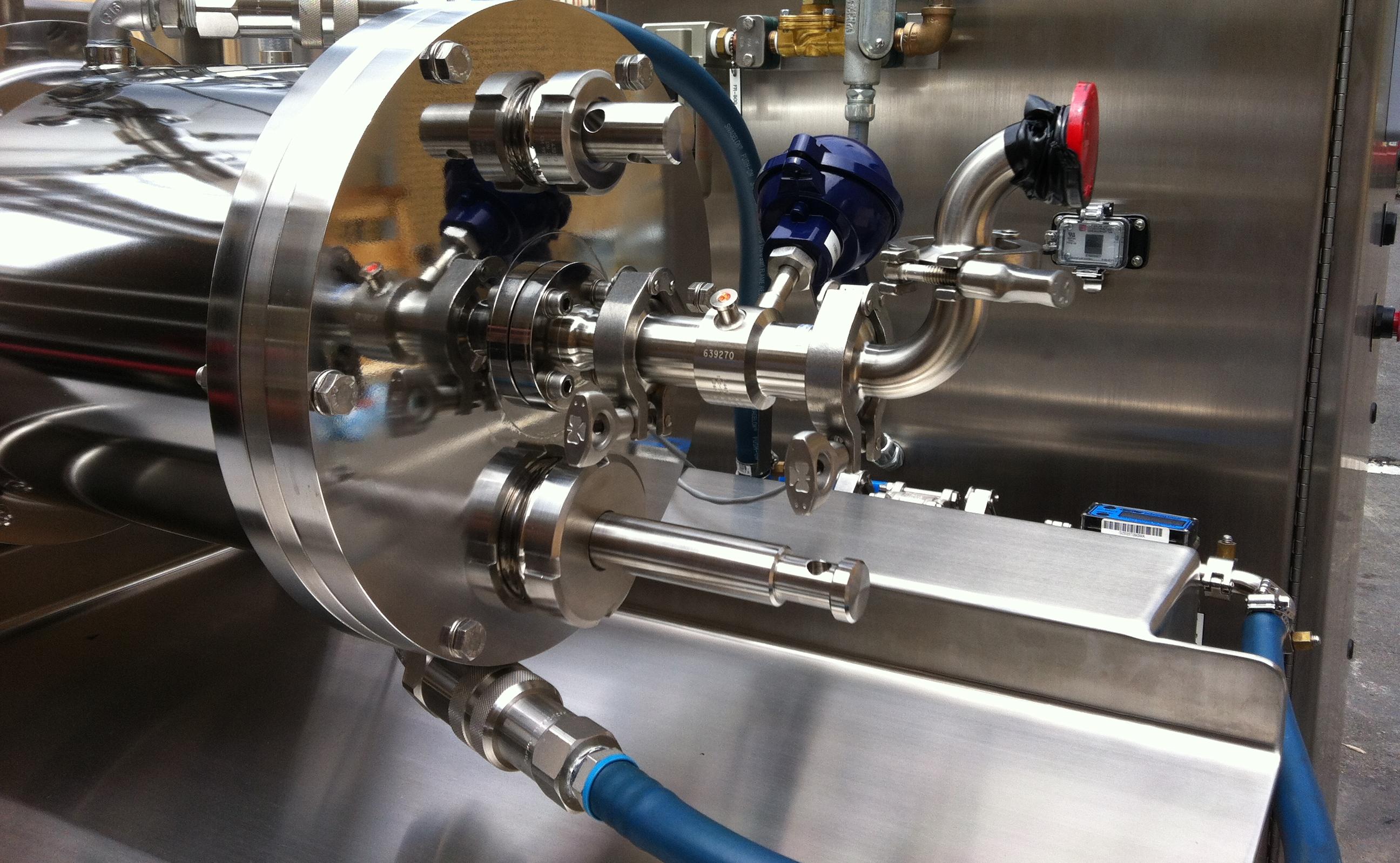

DV 10000 mill appearance

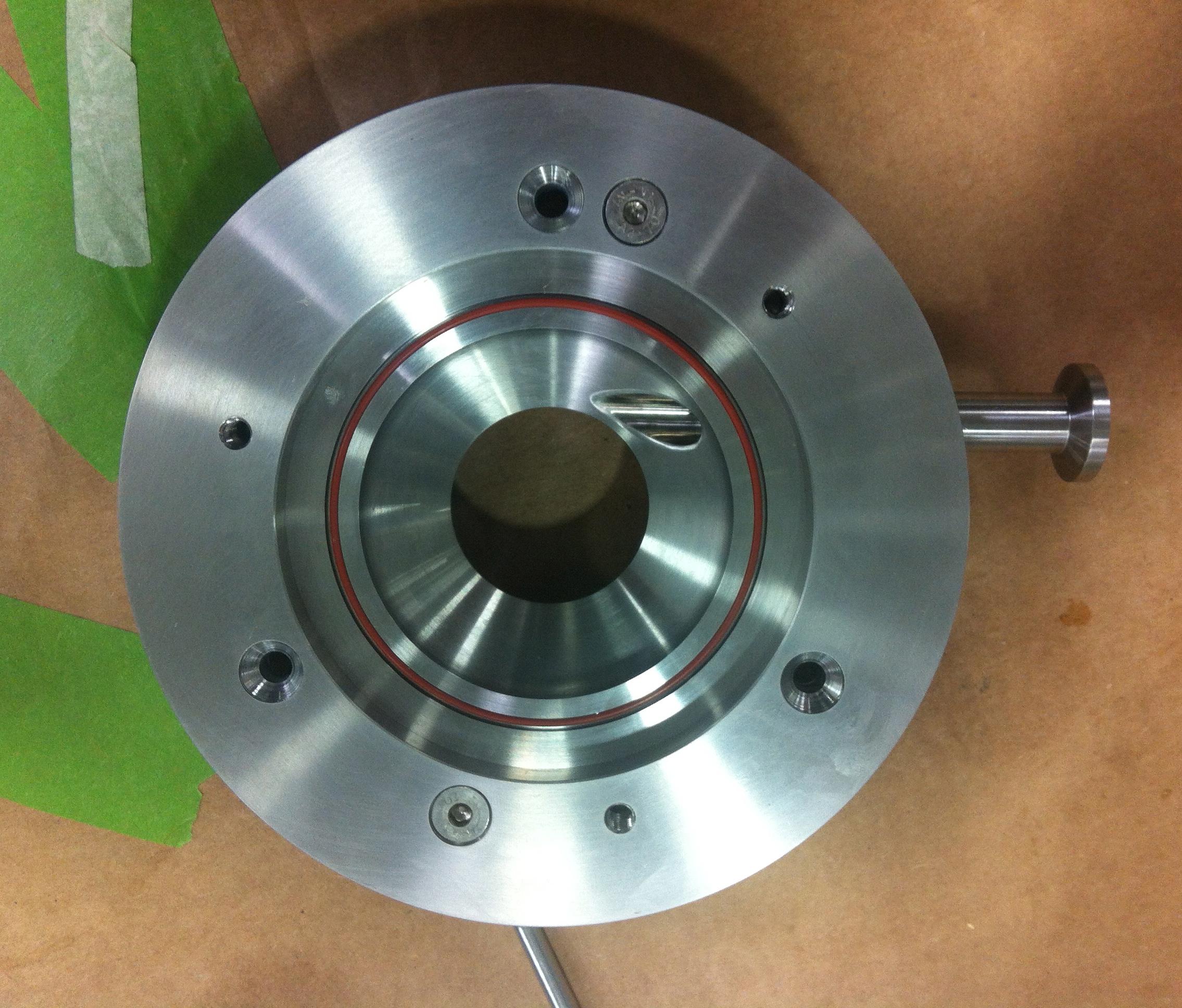

Product out let and plate

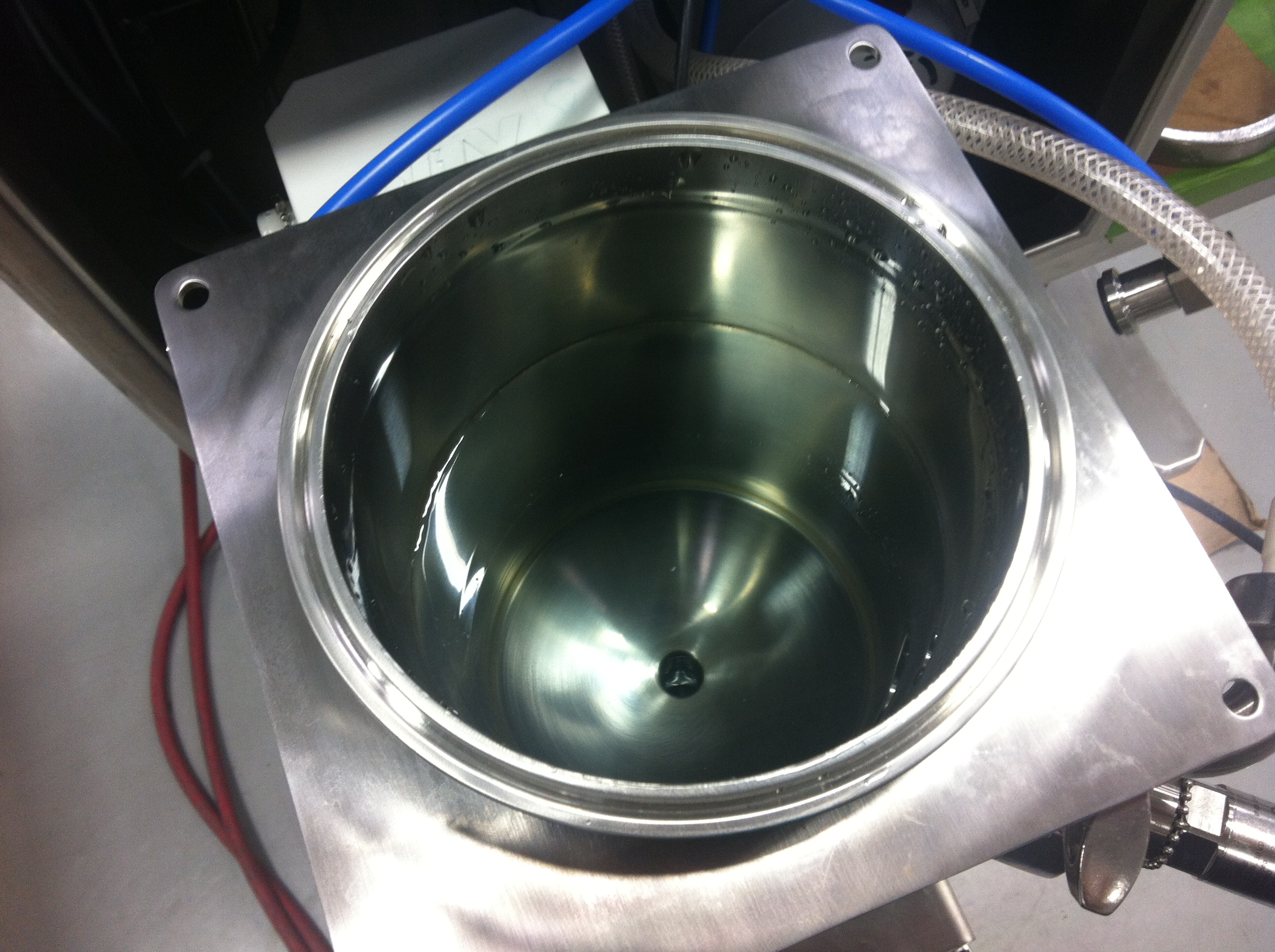

Grinding chamber bottom

|